High Quality Rigid and Flex Circuit Assembly

Our Capabilities

Resources

Ensuring Quality from Design Submission Through Production

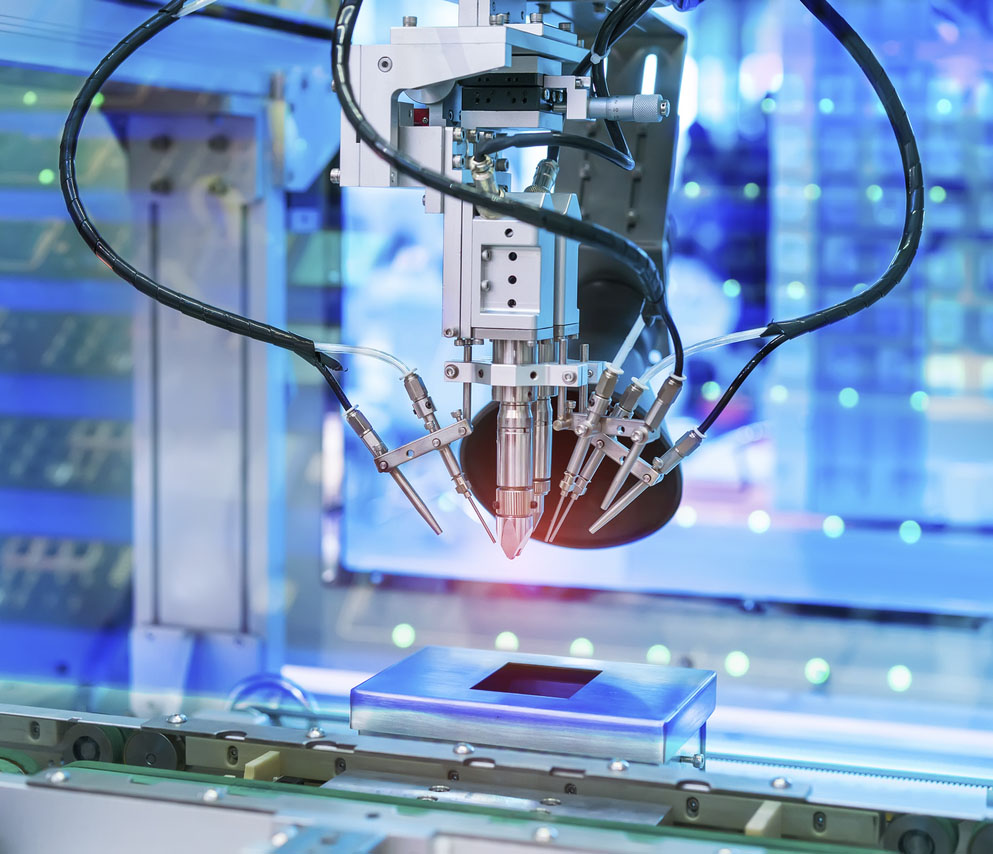

Tramonto Circuits handles every aspect of electronic assembly for PCB, flexible heater, and rigid/flex circuits. With high-quality circuit technologies, rapid process engineering, dependable product assembly, and quality assurance processes, you can feel confident your electronic assembly will be perfect when delivered.

We take several steps to ensure quality at every stage, and 100% of circuits and assemblies undergo a final inspection. These measures have resulted in a historic quality ratio of over 99%.

Design for Manufacturability (DFM) Assessment

Upon submitting your CAD, our engineers conduct a DFM check. This step assesses whether circuits are manufacturable as designed, and ensures they can be consistently and reliably fabricated repeatedly. All designs receive final customer approval before fabrication begins.

In-Process Quality Inspections

At every stage of the manufacturing process, you receive support and guidance from our engineers. We conduct rigorous, multi-point quality checks during fabrication in compliance with the following:

- IPC Class II or Class III Specifications, based on your requirements. Inspection of all solder joints and ensuring circuit board components are in the right location and orientation.

- J Standard (J-STD-001). Inspection of all remaining circuit and assembly components as outlined by industry standards.

When required, additional checks are conducted to comply with UL standards and other applicable industry specifications for the manufacturing of electronic circuits and assemblies.

Final Inspection and Testing

Before shipping, we conduct a final inspection to ensure circuits and assemblies meet IPC Class II or III Specifications. In some cases or when required, functional tests are also available.

Return Material Authorization (RMA) and Corrective Actions

Corrective action processes are in place to identify the root cause of quality issues identified during fabrication or after receipt of your shipment. During this process, our engineers identify and test potential solutions until they achieve a valid result. At that point, we close the corrective action.

Achieving Quality and On-Time Delivery Since 2008

On-Time Delivery

Quality Ratio

24-Hour Quotations

Our Quality Commitment

Tramonto Circuits is committed to consistently providing its customers with high-quality products and services that meet or exceed their expectations. We are committed to:

- Consistent quality of our products

- Continuous improvement

- Our company’s integrity

- On-time delivery

Inspection Equipment and Industry Compliance

All quality inspection equipment is calibrated annually in compliance with ISO and IPC regulations. As an ISO Certified rigid and flexible PCB manufacturer, we perform monthly internal audits in addition to the annual external agency audit. Customers are also welcome to perform external audits as required for internal quality assurance processes and regulatory requirements.