7 Things You Must Know to Design Effective PCBs for Aviation Applications

Printed circuit boards (PCBs) used in aerospace applications must be highly reliable, leaving no margin for error. They must last a long time while being used non-stop in challenging and extreme operating conditions. Unlike most traditional PCBs, ones used in aerospace applications must withstand intense environmental conditions, radiation, chemicals, contaminants, and more.

Aerospace circuits must meet strict standards, including the IPC-A-610E Class 3, which covers high-performance electronic devices that must operate continuously, without interruption, in the most difficult conditions. Some of the applications falling within the IPC-A-610E Class 3 standards are:

- Satellite communication systems

- Navigation systems

- Control systems

- On-board avionic instrumentation

- Applications for processing data on the ground recorded during flights

- Passive detection systems

- Unmanned aerial vehicles (UAVs)

- And more.

This guide explains what you must know to design circuits that can withstand the extreme conditions — and wear and tear — they will experience in aerospace applications.

1. Use Top Quality Materials

Reliability and durability are two non-negotiable requirements for circuits built for use in the aerospace industry. Typically, PCBs must operate continuously for 15 years or more. It’s critical to use high-quality materials that are time-tested.

In many aerospace PCBs, anodized aluminum is used instead of copper because it can help resolve many issues related to heat dissipation. Anodized aluminum delivers a thermal conductivity that is five to ten times higher than traditional materials like FR-4, with ten times less thickness. In addition, it can transfer heat much more efficiently than conventional PCBs. Plus, it significantly reduces the effects of heat-induced oxidation.

2. Leverage Heavy Copper Technology

Heavy copper technology, with copper thicknesses ranging from 2 to 6 oz/ft or more, allows heat to dissipate naturally. No additional cooling systems are necessary, even with high-intensity currents.

Combining heavy copper solutions with thermal vias is often a good idea to further enhance heat dissipation.

3. Always Stick to Standards

Printed circuit boards used in aerospace applications must be designed to operate with minimal maintenance while meeting rigorous safety and quality standards.

To achieve this, designers and manufacturers of aerospace PCBs must follow industry standards. This includes the IPC 6012DS, an addendum to the IPC-6012D. It provides qualification and performance requirements for rigid printed circuit boards for aerospace applications. It’s often considered an enhanced version of the IPC Class 3 standard.

Also important is the AS/EN 9100 aerospace standard. It includes an array of regulations developed by the International Aerospace Quality Group (IAQG). It aims to improve quality and reduce risk in the aerospace sector. This standard has been adopted across the globe.

The AS/EN 9100 standard adds requirements developed specifically for the aerospace industry to the ISO9001 standard. Printed circuits designed and developed for aerospace applications must conform to this standard and be certified they do so.

4. Deliver Excellent Thermal Management

As already covered, PCBs for aerospace applications must ensure excellent heat dissipation without needing to use external heatsinks. In addition to heavy copper technology and thermal vias, solutions like Pyralux AP, FR408, and other metal materials and components can help with the issue. It’s also smart to separate components, which provides more space for heat to dissipate.

5. Take Advantage of Conformal Coating and Surface Finish

PCB finishing materials must withstand extreme aerospace operating conditions. Typical surface finish methods include:

- Electrolytic nickel gold

- Electroless nickel with immersion gold coating (ENIG)

- Chemical silver

- Hot air solder leveling (HASL)

- Lead-free HASL

Typical conformal coating protects against heat, humidity, vibration, and water. The application of conformal coating should be followed by application of acrylic-based spray. It helps protect the PCB from contamination or short-circuiting.

6. Follow Routing Best Practices

The size of PCB traces must be able to handle the maximum current load, ensuring heat dissipation in all operating conditions. For circuits with high-frequency signals, the angles on the traces must be less than 45 degrees. This supports the uniform and dependable transmission of the signal across the circuit.

Electronic components operating at low frequencies must be separated from those using higher frequencies. That’s because high frequencies often generate waveforms and disturbances that impact low-frequency component operation. These issues can degrade signal quality, compromising the effectiveness of applications depending on them.

Clock signals must have appropriate physical shielding by applying casings made of aluminum or similar materials. Rules must also be applied to limit the crosstalk phenomena that can happen between adjacent traces.

7. Use a Combination of Flex and Rigid-Flex PCBs as Appropriate

Flexible and rigid-flexible printed circuit boards are commonly used in satellite and avionics systems. However, compared to industrial or automotive applications, they are typically manufactured with polyimide instead of FR-4. This material can adapt to small spaces, is light and resistant to heat and chemical agents, and is highly durable.

Flex and rigid-flex PCBs are popular in the aerospace industry because they:

- Adapt to small spaces

- Provide high resistance to vibrations, shocks, temperature, and external agents

- Deliver excellent mechanical and electrical connection

- Are lightweight.

Rigid-flex PCBs combine rigid and flexible printed circuit boards. They are permanently connected. Using flex and rigid-flex printed circuit boards can be an ideal solution for challenging applications with space limitations. It provides a secure connection between the parts of the rigid-flex circuit, ensuring both polarity and contact stability and reducing the number of connectors needed.

PCBs for Aviation Applications: The Bottom Line

Printed circuit boards for the aerospace sector that must meet the IPC-A-610 Class 3 and 3A standards have to be designed to deliver high electrical reliability, especially in the most challenging operating conditions.

All aspects of the PCB design process — from selecting the most suitable materials to getting them certified — must be focused on continuous failure-free operation, which can be a significant challenge. Leverage the expert tips in this article to ensure you get everything right.

The Pros and Cons of Flexible Circuit Boards

Should you use flexible printed circuit boards (PCBs) in your devices?

This guide explains the pros and cons of flexible circuits so you can decide if they’re suitable for your device or application.

What is a Flexible Printed Circuit Board?

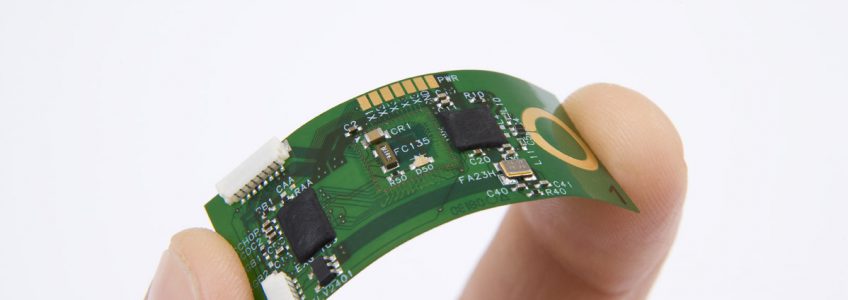

A flexible PCB is a circuit made from dielectric substrate film materials that can bend and twist without breaking. Electrical traces are etched into the surface. Once that’s complete, a protective overlay or cover coat is applied.

Flexible PCBs can be single- or double-sided and also come in multi-layered designs. Designers often combine them with rigid circuit boards to make rigid-flex circuits.

Flexible Circuit Boards: The Pros

Here are some of the positive aspects of using flexible circuit boards.

Pro: More flexible

Naturally, the critical advantage of flexible PCBs is flexibility. You can bend the circuit board to install it into a device. This allows you to build the device you want without structuring it around a rigid circuit. You can bend circuits into virtually any shape to fit any application. They can twist and bend around corners without getting caught on parts.

The entire board is flexible and stays that way for its entire useful life. The materials will not become rigid with age if designed and built correctly. The flexibility should not have any negative impact on the functionality of a device or application.

Pro: Lighter weight and takes up less space

Flexible PCBs are lighter and have slimmer profiles than traditional rigid boards. Instead of being forced to design devices and applications with extra space to fit rigid boards, you can design slimmer and more ergonomic items with flexible PCBs.

Two more pluses are that flexible PCBs help manufacturers reduce material waste and optimize their devices’ interior spaces and functionality.

Flexible PCBs do not add significant weight to devices, applications, and components. You never need to reinforce the interior of a device to support the flexible PCB. You can also meet the required weight and space limitations of items, which is particularly important for wearable technology, medical devices, and aerospace applications. Adding extra weight to these things could make them unusable or negatively impact functionality.

Pro: Replaces components and cable harnesses

When you use a flexible PCB, you do not have to add components or multiple rigid PCBs to support certain functions because they can’t get around internal components. A rigid-flex PCB can be used instead, eliminating cable harnesses. Rigid-flex PCBs are typically thinner than traditional cable harnesses, optimizing the space and weight of internal components.

ZIF connectors can be used to attach a flexible circuit board to a rigid one. ZIF connectors have a wide signal range, including low-level, high-current, and high-speed controlled impedance.

Flexible Circuit Boards: The Cons

Con: Higher cost and longer development time

Flexible and rigid-flexible PCBs cost more to build and have longer build cycles than traditional circuits. That’s partly due to the nature of the flexible materials and the relative newness of the technology. The higher costs may be prohibitive for some projects, such as when the materials and manufacturing of the device cost less than the flexible PCB. However, in the right circumstances, an extra investment in flexible PCB design and development will pay off in a big way.

Con: Size and space limitations

While flexible PCBs have slimmer profiles than traditional rigid ones, they come with size limitations. They cannot be made into very long or wide widths. Plus, flexibility in tight areas may require redesigning the components so they have lower profiles, or you may have to rework component placement to accommodate the flexible PCB. You must also be careful as the flexible PCB can be more prone to damage during handling.

Con: Increased design and stack-up complexity

As the design and stack-up of a flexible PCB increases, so does its complexity. You must follow several guidelines when using flex PCBs to prevent damage and malfunction. Some guidelines include:

- Never use plated through hole vias at bend areas

- Avoid 90-degree bends that can increase the likelihood of damage

- Conductors smaller than 10mils must be placed on the inside of the neutral bend axis and should run perpendicular to the bend

- Conductors must be staggered on multi-layered circuits.

You must also carefully consider the types of coverlays, flexible solder masks, stiffeners, and adhesives used in flex circuits. The materials differ from those used in rigid PCBs, which can increase costs and change the thickness of the board.

The Pros and Cons of Flexible Circuits: The Final Word

Flexible PCBs are becoming the go-to component for small, thin, and lightweight equipment. They allow applications to function properly while maintaining a smaller profile than equipment using larger traditional circuit boards.

Not sure if flexible circuit boards are the right solution for you? The experts at Tramonto are always available to help evaluate your application and advise on the proper circuit type for it.

Printed Circuit Board Design Checklist

Is your printed circuit board (PCB) ready for production? This step-by-step checklist will help determine whether you’ve completed everything necessary to move your design to prototyping and production.

Before Submitting Your Board for PCB Design Review

- Look for unrouted nets

- Repour polygons

- Check that the board has a complete silkscreen, including:

- Warning and hazard labels and appropriate icons

- Company and product logos

- Copyright information

- Make sure connectors are labeled and pinouts are called out as needed

- QA/test block with barcode, along with blank areas for a serial number and dates

- QA/test checkmarks

- Review board name, print date, and revision number

- See if there are designators on the silkscreen, then check that:

- Every designator is close to — and identifies — the related component

- All designators are in one or two orientations

- Text size and font will be readable after the fabrication process is complete

- ICs have pin one marked

- The pin one marker should not be placed below another component

- Update the PCB from its schematics to make sure the schematic and board are synched

- Check that the design rule report is error-free

- Check that there is a design rule to catch nets with only one pin

- Check that the board outline appears on a mechanical layer that will go to the fabricator

- Ensure fiducials are present for the assembly. They must meet the following criteria:

- A minimum of three board-level fiducials are included

- Two fiducials diagonally oppose each other across all fine-pitch components

- Mounting points have adequate clearance for the designated washer and screw head

- If an enclosure model is available, check that it’s been tested against the board to make sure there will be no interference between the enclosure and components

- Ensure all components, including mechanical items, have the correct 3D models

Your board must be fully production-ready before sending it to colleagues for a design review check to avoid useless effort.

Submitting a PCB Design for Review

PCB Design Review: Layers

- Ensure that the layer stack and substrate heights meet your fabricator’s specifications or that they can meet yours

- Review the copper thickness on all layers to make sure it matches the target fabricator’s specifications or that there is a callout for the required copper thickness

- Check that there is at least one continuous, unbroken ground plane

- If the PCB has controlled impedance nets, check that they’re correctly set up on the layer stack and in the design rules

- Ensure the keep-out track matches the shape of the board

- Check any board cutouts or slots used for a keep-out barrier to prevent nets from crossing milled areas

A PCB stackup table developed as part of your front-end engineering specifications can be helpful. It provides a visual comparison against the data in your PCB editor. A table provided by a fabrication house or manufacturer is the best resource.

PCB Design Review: Signal Path

- Check that the ground plane has adequate current-carrying vias near connectors and voltage/return sinks

- If needed, review voltage planes and areas to ensure they have sufficient connection vias for current requirements

- Check tracks to reference planes to make sure they are wide enough to meet current requirements

- Ensure that there are an adequate number of vias for the current-carrying capacity of traces

- Check the minimum track widths for current-carrying nets and ensure they’re adequate

• Consider whether a design rule is necessary - Ensure all ground pins have a via to the ground plane

- Make sure there is a continuous ground plane within one signal layer of any signal trace

- Check that controlled impedance traces have the proper net rules and impedance profile

- Ensure that differential pair tracks are as close together as possible

- Check that differential pair track lengths match

- Make certain high-speed signals are length-matched, including:

• DDR

• Ethernet

• HDMI

• LVDS

• MIPI

• PCIe

• USB3+ - Ensure each signal trace has a constant impedance along its length

If the trace changes layers, its impedance should remain the same - Check that traces longer than 1/6th of the rise or fall time of the signal have been simulated:

• Ensure termination resistors — or another form of termination — are present to prevent ringing or overshoots

• Ensure termination resistors are in proper locations - Make certain long traces that hug other traces have been simulated for crosstalk

- Review all high-speed traces that run over a continuous ground pour

- Make sure that sensitive nets don’t run below noisy components

- Ensure that vias for decoupling capacitors aren’t shared

- Check that every decoupling capacitor has its own via for VCC and GND direct to reference planes

- Ensure the xSignals package includes features that can help automate checks after the PCB layout is complete but before a more rigorous engineering team manual review.

PCB Design Review: Components

- Ensure through-hole pads are set to plated if they need to be soldered

- Check there is sufficient clearance for:

• Pick and place heads in the production process

• Hand assembly in prototypes

• Soldering pen tip access if rework is needed - Ensure bypass capacitors are placed as close as possible to IC power pins

• Under 15mm - Check that termination resistors are as close as possible to the signal source

- Make sure crystal/oscillator clock sources are as close as possible to IC clock pins

- Ensure EMI/RFI filtering is as near as possible to the exit point

• Board edge, connector, or shield - Make sure that potentiometers raise signal/voltage when turned clockwise

- Check that programmable devices have programming header/pads that are accessible

- Ensure that no high thermal mass components, such as large transformers or inductors, are too close to small components

- Ensure that component placement makes short track lengths a priority for high-speed signals

- Ensure that copper areas are large enough for heat-sinking high-dissipation devices, including:

• Chargers

• High-frequency gate drivers

• High power LEDs

• High-speed microprocessors

• Linear regulators

• MOSFETs

• Motor drivers

• Power amplifiers

• Switched-mode power supplies, including LED drivers

PCB Design Review: Testing

- Make sure test pads are far enough from the board edge to allow fixturing

- Check that test pads don’t create stubs or impedance mismatch on high-speed nets

- Ensure that components do not obstruct access to test pads for manual or automated testing

- Make sure test pads are clearly labeled for prototypes

- Check any signal needed for inspection or testing, includes a test point

- Ensure test points are located on the same side of the board, ideally:

• On the bottom of the board for bed of nails fixture assets

• On the top of the board for test equipment manual access

Test points are sometimes placed in inconvenient locations, often too close to other pads or near board edges. There is a risk of shorting when probing if placed near other pads. They could interfere with the enclosure or mechanical mounting when placed too close to the board edge. Because test points don’t often have a placement spec, it’s a good idea to consider moving them and identify alternative locations during a design review.

PCB Design Review: Protection/EMI/EMC

- Ensure correct creepage and clearance rules are in place for all high-voltage nets

- See if separate earth tracks/paths are needed for ESD

- Ensure there are decoupling capacitors next to connectors and vias that require them

- Check that TVS diodes or other ESD mitigation component pads are in series with the track to the component

• The ESD event must pass through the component pad before arriving at a sensitive device - Check that no track stubs/net antennas go to test points or unused connector pins

- Check that high-speed signals are routed as directly as possible

- Make sure any track carrying more than 100mA is wide enough for the current

If the PCB will be placed in an enclosure with little or no airflow, calculate or simulate the width for an internal layer instead of an external layer - SEE if an RF shield is NEEDED anywhere on the board and if it has an adequate footprint

- If it is a two-layer board, ask yourself:

• Are there any ground loops?

• Is there an unbroken ground pour under each high-speed trace?

• Is the ground track of adequate size for the return current of the device? - If multiple grounds exist, ensure they are tied together at a single point.

PCB Design Review: Panels

- Make sure there is enough frame area to handle conveyors and clamping

- Check that the silkscreen includes:

• Blanks for QA/testing marks

• Board part number and revision

• Company name

• Machine name

• Panel barcode

• Print date - Ensure that panel fiducials are present

- Look for an origin identification mark

- Check that impedance/layer/other test areas are present if needed

- Make sure that V score, milling, and tab layers are present and aligned with the board if they aren’t included in the board file

Check the panel isn’t too large for the board thickness and any milling (i.e., low flexibility/bounce)

Conclusion

While we’ve tried to make this checklist as comprehensive as possible, we may have left some things off that could be critical to your business. There may also be review items on here that do not apply to your company or project. Feel free to tailor this checklist to meet your specific needs.

Need help designing circuits for your applications? The experienced professionals at Tramonto are always available to answer your questions. Contact us today.

Keypad Design Factors That Impact Performance

Keypad assemblies designed correctly and made with suitable materials can be highly reliable. That’s not the case if poor design and manufacturing choices are made.

The top factors that impact keypad longevity are:

- Contamination entering the switch cavity

- Contamination inside the switch cavity

- Exceeding switch contact point electrical ratings.

We’ll look into these in greater detail and explain how to avoid problems that can shorten keypad life. But first, let’s gain a foundational understanding of keypad assemblies.

Keypads: The Basics

There are two types of low-profile keypad assemblies.

One is the conventional flexible printed membrane keypad. The switch circuitry of this type of keypad is silver conductive polymer inks screened onto 1.25 mm (5-mil) polyester sheets. A thin adhesive or polyester layer with a hole at each switch location separates opposing polyester circuit layers. When a finger puts pressure on the switch, it deforms the top circuit layer, completing the connection to the bottom circuit layer. A metal snap dome or embossed dome formed in a polyester sheet (sometimes called poly domes) indicates the proper pressure point.

The second type of keypad assembly incorporates a printed circuit board (PCB) with metal snap domes. All the keypad’s circuitry is on the printed circuit board. The snap domes indicate where to apply pressure. They also serve to complete a circuit path to trigger the switch.

Both types of keypads are typically finished with a graphic overlay or other mechanism, such as a plastic or molded rubber key top, to more clearly indicate where to trigger the switch.

Now that we have a foundational understanding of how switches work let’s examine how they can be corrupted and the best ways to extend their lives.

Contamination Entering the Switch Cavity

The first factor that adversely impacts keypad reliability is contamination entering the switch cavity. Contamination can take the form of non-conductive dirt, such as lint, dust, and other particles. It can also be liquid containing suspended or dissolved dirt.

Keypads, no matter which type they are, all contain air inside the switch cavity. When a finger presses on the switch, the air inside the cavity must reduce in volume, making it possible to complete the circuit. That’s why it’s necessary to provide a way for the switch cavity air to escape. Air escape is typically accomplished by cutting narrow air channels in the spacer layer between the silver-printed polyester circuit layers running from the switch cavities and its edges. Vents in PCB keypads are usually simple holes in the printed circuit board under the snap dome.

The issue is that vents not only let out air but also allow contamination into the switch cavity. Pressing the switch pushes out air. When the finger is removed, a partial vacuum is formed in the switch cavity, which sucks in outside air along with dirt particles or liquid. Contamination will prevent the electrical switch from closing correctly because it’s likely to be non-conductive, resulting in a faulty switch.

External contamination can be prevented from entering a switch by designing it correctly and working with an experienced circuit board manufacturer like Tramonto Circuits.

Contamination Inside the Switch Cavity

The second factor that negatively impacts keypad reliability is contamination in the switch cavity. It takes the form of oxide growth on the switch contact surfaces. Circuit performance of common metal oxides except silver can be affected by oxide growth, making them non-conductive, resulting in faulty switches.

Silver-printed polyester membrane switches are, by their nature, immune to oxide growth-related failures. That’s because silver is the only common metal that has a fully conductive oxide. Leveraging silver in circuits is a proven way to ensure good performance over time.

Using gold plating over nickel barrier plating can prevent non-conductive oxide growth on PCBs. An electro-less gold plating process provides two to four micro-inches of thickness. This thickness is necessary because the metal snap dome feet touch the gold surface, which will wear down thinner plate.

Almost all metal switch domes today are manufactured from stainless steel alloy. Many believe stainless steel doesn’t rust. However, that isn’t wholly true. Visible rust is prevented by the formation of chromium oxide (a form of rust) on the surface of stainless steel. A small amount of chromium is found in all stainless steel alloys. The chromium oxide is invisible, sealing the surface and making it impossible for iron particles to form iron oxide. Put simply, chromium oxide makes stainless steel stainless.

As with most metal oxides, chromium oxide is non-conductive, making it unsuitable for switch surfaces. Stainless steel domes are typically plated with nickel, and nickel oxide does a relatively good job of preventing chromium oxide growth. While this is true, gold plating also prevents chromium oxide growth and electrically performs better than nickel. The issue is that standard gold plating processes can cause significant mechanical damage to highly stressed, punched stainless steel snap domes.

Standard gold plating is hydrogen-based. It makes stainless steel brittle, which can negatively impact the life of metal snap domes, sometimes by as much as 90 percent. A knowledgeable circuit manufacturer like Tramonto Circuits can leverage the correct form of gold plating chemistry to prevent this problem.

Clearly, internal contamination of keypad circuits is a complex and common issue. You owe it to yourself to work with an experienced PCB designer and manufacturer to ensure your switches are durable and long-lasting and don’t fail in the devices you use them in.

Exceeding Switch Contact Point Electrical Ratings

A third issue that negatively affects keypad dependability is exceeding the electrical ratings for switch contact surfaces. Low-profile keypads are intended for logic-level circuits. Any excess open circuit voltage or closed circuit current — or reactive components in the switched load, such as inductors or capacitors, will rapidly deteriorate switch surfaces.

Once switch surfaces are damaged in this way, switch performance issues such as intermittent operation, long contact bounce on make or break, and high resistance will occur. Once it happens, it’s irreversible. Of all the issues covered in this piece, exceeding electrical ratings is the most significant.

When a switch controls high voltage, high current, or reactive loads, the loads must be isolated from the keypad’s switch surfaces by solid-state relays or electronic buffering. An experienced circuit designer and manufacturer like Tramonto Circuits can help prevent these issues and possible related device failures.

Keypad Circuit Issues: The Final Word

In short, a device or application is only as good as its keypad. The keypad must last as long as the device’s expected life.

The keypad — and the circuits controlling it — deserve as much design and manufacturing attention as the rest of the devices or applications they control. You owe it to yourself to partner with a top keypad circuit developer like Tramonto Circuits to get the durable circuits you need delivered on time and within budget.

How to: Know for Certain Your Medical Circuits are Safe

More than almost any other type of circuit, it’s critical to ensure that it is designed and developed specifically for the medical industry. Here are some essential things to consider to make certain your printed circuit boards (PCBs) are completely safe and effective.

Signal Integrity

Signal integrity is critical for medical circuits. That’s because electrical signals must stay clear of interference and noise while moving along the traces. The layout and routing selection must follow best practices to minimize even the slightest bit of noise on traces. A knowledgable provider like Tramonto Circuits will ensure this is the case.

EMI/EMC Compliance

EMI/EMC compliance is vital for circuits used in medical devices. Electrical interference can impact how the device operates along with other nearby equipment and systems.

Power Consumption

Power consumption is a crucial consideration when designing medical circuits. Specific devices require low power levels for portability or to extend battery life. It’s critical that the board layout not limit power efficiency gains. Plus, all materials used must minimize energy needs without negatively impacting performance. An experienced medical PCB designer and manufacturing company like Tramonto Circuits can address these factors.

DfM Design

Medical circuit boards must meet tight standards for precision and quality as part of an IPC 6012 Class 3 build. DfM ensures the most stringent aspects of the design are met in the manufacturing process.

Dependability

Of course, high reliability is critical for medical circuit boards. The failure of a medical device could put someone’s life at risk. Designers and manufacturers must select parts and materials that can withstand the operating environment. Temperature fluctuations and humidity levels must be considered to minimize premature degradation or failure.

Quality Control

Medical device manufacturers must consistently employ the highest level of quality control to ensure they meet the required standards and specifications. The manufacturing process must be carefully monitored and controlled to ensure the PCBs meet specified tolerances, dimensions, and electrical requirements.

Traceability

Medical device makers must be able to track every device component from the original design to the finished product. This requires strictly following traceability protocols, including:

- Component tracking

- Lot tracking

- Serial number assignment

- And more.

Medical device makers must maintain complete documentation of the development and manufacturing process, including material traceability, testing results, and validation reports. Tramonto Circuits has extensive experience with all forms of documentation.

Material Selection

The materials used in medical PCBs must be carefully chosen to ensure they align with the device’s intended use, sterilization method, and regulatory requirements. They must be free of contaminants and impurities. The materials used in a medical PCB must also be safe and reliable. They should be durable and flame-retardant. All must be UL-approved, as well.

Environmental Controls

The manufacturing location must be carefully controlled to ensure that the circuits are made in a clean environment with no contaminants or particles that could negatively affect performance or safety.

Testing and Validation

Medical circuits must be tested and validated to ensure they comply with standards and meet specifications. This includes testing for electrical and environmental performance, along with compatibility with the other components of the device.

Medical devices are life and death. You can’t take chances with a designer or manufacturer that doesn’t have extensive industry knowledge. Tramonto Circuits has decades of experience designing and developing custom circuits for a wide range of medical device manufacturers. Contact one of our helpful and knowledgeable representatives to learn how we could support your organization.

Medical Device Regulations for PCBs: What You Must Know

Adhering to industry-specific rules and regulations is essential for most products. It’s even more critical for manufacturers creating printed circuit boards (PCBs) for medical devices and device makers to follow them to the letter to ensure the equipment performs as intended. It’s a matter of life and death.

This guide explains what medical device manufacturers and the circuit producers that support them must know about regulations related to developing safe and effective PCBs and medical equipment.

Medical Devices Dependent on Circuit Boards

Devices that are heavily reliant on circuits include:

- Blood pressure monitors

- Heart monitors

- Pacemakers

- Thermometers

- Cochlear implants

- Imaging and diagnostic instruments

- EMG (electromyography) activity systems

- Neurostimulators

- Handheld monitors.

These devices must function precisely all the time to help diagnose and treat patients. They require many inspections during the manufacturing process and once the machines are in use. Several bodies across the globe have issued guidelines for these instruments.

What are the Medical Device Regulations for PCBs?

Authorities like the Institute for Printed Circuits (IPC), the International Organization for Standardization (ISO), and the U.S. Food and Drug Administration (FDA) have all released standards related to circuit boards used in medical equipment. The guidelines include all aspects of the development and manufacturing process all the way to final approval. It’s mandatory to follow all these regulations during medical PCB assembly to ensure they are reliable and don’t cause harm to patients.

Let’s go deeper into each of these organizations and their regulations.

IPC

The Institute for Printed Circuits is an organization that regulates the assembly and production of electronic components and assemblies. The group has developed and released several critical standards:

- IPC-A-600: Establishes the minimum acceptability requirements for printed boards.

- IPC-A-6012: Describes the qualification and performance requirements for PCBs.

- IPC-A-610: Explains the requirements for acceptable electronic assemblies.

The IPC also has standards for:

- Wire harnesses

- Soldering

- Enclosures

- Cables.

Visit the IPC website to learn more about applicable standards.

ISO

ISO is the acronym for the International Organization for Standardization. The group develops and publishes a range of standards related to the design, manufacture, and testing of circuit boards.

The ISO 9000 standard is mandatory for original equipment manufacturers (OEMs) to certify the safety of medical equipment and its proper function. ISO 13485:2016 is an updated quality management system for MedTech devices centered on current industry practices. It places a strong focus on risk management along with risk-based decision-making. It also provides information related to industry regulatory concerns.

FDA

The United States Food and Drug Administration’s (FDA) Center for Devices and Radiological Health (CDRH) imposes laws on companies that manufacture, re-label, re-package, and import medical devices in and into the U.S. In addition, CDRH monitors electronic products that emit radiation, including X-ray equipment, lasers, ultrasound devices, and others.

FDA categorizes medical devices into three classes:

- Class 1 devices include adhesive bandages, sunglasses, IV (intravenous therapy) stands, and other things considered relatively low risk.

- Class 2 devices include intermediate-risk instruments like powered wheelchairs, syringes, surgical masks, and other similar items.

- Class 3 devices include many high-risk items that use PCBs such as heart valves and implantable neuromuscular stimulators. This category is the most stringent and closely monitored by the agency.

The many facets of FDA compliance are organized into the following categories:

Establishment registration

Domestic and foreign manufacturers must register with the Food and Drug Administration. This takes place electronically unless the organization issues a waiver. Manufacturers must complete an annual verification of their registration information between October 1 and December 31 of each year. Overseas manufacturers must also appoint a U.S. representative.

Medical device listing

Manufacturers must comply with medical device listing requirements, including the following types of businesses:

- Contract manufacturers (CM)

- Contract sterilizers

- Manufacturers

- Manufacturers of components and accessories sold directly to end-users

- Relabelers and repackagers

- Remanufacturers

- Reprocessors of single-use devices

- Specification developers

· United States manufacturers of devices for export only.

Quality system regulation

Quality system regulation involves defining and meeting requirements related to various aspects of medical devices, including:

- Designing

- Fitting

- Labeling

- Maintaining

- Packaging

- Procurement

- Production

- Storing.

Manufacturing facilities are subject to FDA inspections to ensure compliance with their standards.

Labeling requirements

According to the FDA, labeling includes the physical device label, its description, and any additional informational text that is included with the device.

Medical device reporting (MDR)

The fundamental rationale behind the Food and Drug Administration’s MDR regulation is to identify significant adverse issues related to medical devices and to monitor them on an ongoing basis. It’s a requirement to notify the organization about anything that may have caused severe problems, injuries, or death. All device malfunctions must also be reported. The goal is to uncover and fix issues as soon as possible.

Premarket notification 510 (k)

This law, the Medical Device User Fee and Modernization Act, allows the FDA to conduct medical device premarket notification 510 (k) reviews and charge fees for it. (Certain businesses could be eligible for reduced costs.)

Under this law, a business cannot distribute a device requiring 510(k) submission until the FDA demonstrates valid equivalence.

Premarket approval (PMA)

Class III products require premarket approvals because they present a significant risk of illness and injury and cannot be compared directly to less-risky class I and II products. Premarket approval is a highly complicated process that includes submitting clinical data to support any claims about the device.

Medical Device Regulations: The Final Word

Complying with the vast array of PCB-related regulations is complicated. That’s why you shouldn’t go it alone or work with an inexperienced circuit designer or manufacturer. Turn to the experts at Tramonto Circuits to get the support you deserve. Contact a friendly and knowledgeable representative to learn how we can support you.

10 + 1 Circuit Design and Manufacturing Issues and How to Prevent Them

Printed circuit boards (PCBs) are key parts of many electrical devices, connecting critical components. Global demand for circuits has risen exponentially in recent years, and many less-than-reputable actors have entered the industry.

This guide explains common PCB issues (often found in circuits produced by less-experienced providers) and how to avoid them so the devices you use them in perform as intended, providing a high level of dependable service for years to come.

What Is PCB Failure?

PCB failure occurs for many reasons. The end result is that the PCB no longer functions as intended, which can lead to device breakdowns or complete failure. Because PCBs are used in many electronic devices that could malfunction in perilous situations, such as medical wearables, airplane, automobile, and hospital equipment, any possible issues must be identified and prevented — and when they happen, quickly fixed.

Any company looking to keep their electronics running smoothly can prevent PCB failure — and recover from it when it occurs — by understanding why it happens.

The complexity of the PCB design and manufacturing processes introduces many opportunities for issues to arise. Some failures result from design mistakes, such as inadequate clearances or incorrect measurements. Design errors can negatively affect the functioning of the products they’re used in. Others may be the result of issues in manufacturing, such as drilling errors or over-etching. Manufacturing mistakes often result in catastrophic consequences.

The good news is that most of these problems can be avoided by working with professionals who have a deep knowledge of the PCB design and development process and know about common PCB manufacturing problems and how to avoid them.

Following strict design and manufacturing rules and considerations can prevent component failure, connection issues, and other circuit board-related problems.

Here are some common things you may encounter if you work with less-than-reputable circuit manufacturers or those not experienced in your industry.

1. Plating Voids

Plated through-holes are copper-coated holes in a PCB. They allow electricity to move across the circuit. A PCB board fabricator drills holes through the circuit board to create them. Then, through an electroplating process, a layer of copper foil or a copper coating is added to the surface of the material and along the walls of the holes. This disposition process places a thin layer of electroless copper onto the circuit. Finally, additional layers of copper are added and etched to create the circuit image.

The deposition process is not a perfect one. Sometimes, it results in voids in the plating, which are gaps or holes. The plating voids are problematic because they prevent the electrical current from passing through the hole, making it ineffective.

The plating voids happen because of the following:

· Contamination

· Air bubbles in the material

· Inadequate cleaning of the holes

· Insufficient catalyzation of the copper in the deposition process

· Rough hole drilling.

Defects can be avoided by cleaning the material properly after drilling and closely following the manufacturer’s drill directions during use. You can avoid these issues by working with a well-qualified and experienced PCB manufacturing company.

2. Inadequate Copper-to-Edge Clearance

Copper is an incredibly conductive metal. It’s also relatively soft and vulnerable to corrosion. To prevent corrosion, the copper is covered with other materials.

The issue: when a PCB is trimmed, part of the coating can also be cut, exposing the copper below. This negatively impacts the board’s functionality, resulting in shorts and shocks.

This issue can be prevented by ensuring the space between the edge of the copper and the edge of the board (often referred to as the copper-to-edge or plate-to-edge clearance) meets the standards for the type of board being manufactured. A complete design for manufacturability (DFM) check by an experienced manufacturer like Tramonto Circuits typically identifies possible problems.

3. Poor Quality Soldering

Improper soldering during the PCB assembly process can result in significant consequences. One example of this can happen when a technician doesn’t heat the solder enough, referred to as cold soldering, which can result in circuit failure. In addition, when moisture enters the soldering process, it can contaminate the PCB pad and other components.

This contamination can cause PCB components to experience connection problems and possibly burn up. The best PCB manufacturers use visual or enhanced X-ray inspections to find bad soldering.

4. Slivers

Slivers are narrow wedges of copper or solder masks produced during printed circuit board manufacturing. These slivers are often created during the etching process.

The slivers can connect to other pieces of copper or expose copper plating that the solder mask should protect. The first issue can result in a short. The second can cause the copper to corrode over time. Both of these things can reduce the life of the circuit board.

Slivers can be prevented by designing boards with sections of minimum widths. A manufacturer can identify slivers with a DFM check.

5. Missing Solder Mask Between Pads

The solder mask is on top of the circuit board’s copper layer. It prevents the copper traces from accidental contact with other metal, solder, or conductive bits. It also acts as a barrier between the copper and the environment, which prevents corrosion and protects the circuit board’s handlers from electrocution.

In some circuit boards, the solder mask may be partially or entirely missing. This exposes the copper and can result in solder bridges forming between pins. When this happens, it can result in a short circuit and reduced corrosion protection, which can negatively impact the functionality and longevity of the PCB.

This defect is typically the result of a design oversight. The solder mask is undefined, or the settings for a larger board are carried over to a smaller one. This results in pad holes that are too large for the smaller printed circuit board.

All this can be prevented by checking the design before manufacturing, something a reputable manufacturer like Tramonto Circuits will do.

6. Acute Angles in Circuits

Acid Trap is the common term for acute angles in a circuit. The acute angles trap acid during the circuit board etching process. This allows the acid to build up in the corner of the angle, which keeps it there for longer than necessary. In this situation, the acid eats away more than intended, which can compromise a connection. This results in a defective circuit, which can cause severe problems in the future.

Experienced designers are aware of the issues related to acute angles and circuit boards. They are knowledgeable enough to avoid them.

7. Badly Manufactured Components

Another cause of printed circuit board failure happens when the engineering team uses poorly manufactured components. During the PCB production process, any physical damage because of the wrong components can harm the PCB, leading to power failure. Common circuit assembly defects and faults from poorly manufactured components include connection issues and loose parts. Also, residual flux (a substance used during soldering) left on a circuit panel can cause significant damage, making it necessary to repair the circuit board. Experienced manufacturers always use the right high-quality components in their PCBs.

8. Starved Thermals

Thermals are small traces surrounding pads. They’re used to connect pads to the plane. They allow the pads to disperse heat effectively and are critical for the soldering process.

Voids between the thermal and the rest of the plane — or the thermal and the pad — can lead to an incomplete connection. When this happens, it reduces the effectiveness of the heat transfer system the thermals create.

Starved thermals take much longer to transfer heat from pads to the rest of the plane, which can be problematic during soldering or if the circuit is under heat stress. A thermal pad with improper heat transfer may solder in an unusual way. It will also take unusually long to reflow, extending the assembly time. After manufacturing, circuit boards with starved thermals may deliver insufficient heat transfer and are often prone to overheating and heat damage.

The source of these issues can most often be traced back to the manufacturing process. These thermal connections are usually designed correctly in a computer-aided design (CAD) system but are somehow manufactured with a reduced connection to the plane. Manufacturing problems during thermal molding or machining, including over-machining or improper molding, can all lead to this issue. When it happens, it’s usually best to replace the thermal.

An experienced circuit manufacturing company like Tramonto Circuits can prevent faulty thermals, identify them when they happen, and replace them before any harm can occur.

9. Electromagnetic Issues

Electromagnetic compatibility and electromagnetic interference are two problem areas when it comes to circuit board design. Electromagnetic compatibility (EMC) is the generation, propagation, and reception of electromagnetic energy. Electromagnetic interference (EMI) is an unwanted effect of EMC that can cause damage. Too much EMI can cause products to react intermittently and not work as intended. It is typically the result of a design flaw.

EMI can be lowered by expanding the circuit board’s ground area and compartmentalizing the board and signals specifically for EMI. In addition, 90-degree angles must be avoided for most components because they can increase EMI interference. Also, use shielded cables during cable assembly and metallic packaging to absorb EMC and reduce EMI.

10. Environmental Contamination

Environmental factors can negatively impact PCB quality. PCBs exposed to dust, moisture, heat, and cold are likelier to fail. For instance, changes in temperature can make elements on the circuit contract or expand, which could damage or warp the soldering joints and boards themselves. Consulting with an experienced manufacturer like Tramonto Circuits can help mitigate these concerns before boards are fabricated.

Dust around a circuit board can build up over time, clogging the board, which can cause it to overheat. Also, moisture can result in corrosion, rust, and oxidation, damaging the PCB.

Plus 1: No or Inadequate DFM Check or Poor Communication

This guide reveals many things that can go wrong when designing and manufacturing PCBs. The good news is that all of them are preventable. That is why it’s so critical to partner with an experienced PCB manufacturer that runs DFM checks on the designs before they begin building them.

DFM is short for Design for Manufacturability.

DFM checking is the process of reviewing a circuit board layout to identify and minimize any issues that could occur during the fabrication and assembly process. DFM ensures that the design will result in a consistent product that performs as expected dependably. Unlike other standards that only consider how the PCB will potentially work, DFM looks at how the circuit board could break down.

Minimizing these issues requires a specific kind of expertise. Only a few of the design flaws covered in this piece are flagged by CAD software. That’s because it’s not designed to look for these possible issues. A sound DFM check, however, is focused on identifying these potential problems, drawing from an extensive and specialized database of design checks. All these checks may not apply to your specific circuit board, especially if it’s experimental. However, they’re critical to consider before manufacturing begins.

While DFM checks are a relatively common practice for most designers and manufacturers, many don’t understand or communicate design gaps properly. This can result in severe problems down the road.

That’s why you must partner with a custom PCB company like Tramonto Circuits that provides a thorough DFM check backed by a knowledgeable, communicative, and professional staff that will walk you through any issues that may arise with a circuit design or during the manufacturing process. Contact the experts at Tramonto today to find out how we can support you in developing circuits you — and your end users — can depend on.

Challenges of Flexible Circuit Assemblies

Are you finding it challenging to procure suitable flexible circuits? It’s a fast-changing industry, and it can be difficult to stay up-to-date on the latest trends. This guide explains everything you need to know to have a complete understanding of the challenges associated with manufacturing flexible circuits. It will provide you with the information you need to find the right supplier for you.

What are Flexible Circuits?

Flexible circuits, also known as flex circuits, are electronic circuits made of flexible materials such as plastic and polyimide. They are widely used in various industries, including aerospace, medical, and automotive, because of their ability to bend and conform to different shapes and sizes.

What is the Demand for Flexible Circuits?

According to a recent report by Maximize Market Research, the global market for flexible circuits was $32.65 billion in 2022. That’s expected to grow by 8.23 percent annually to $56.81 billion in 2029. Companies that use flexible circuits could find it challenging to procure the components they need as demand increases.

What are the Challenges Associated with Manufacturing Flexible Circuit Boards?

The assembly of flexible circuits presents several challenges that manufacturers must overcome to ensure reliability and functionality.

Equipment Challenges for Manufacturing Flexible Circuits

One of the biggest challenges of flexible circuit assembly is how complex the process is. Unlike rigid circuit boards, which are typically built using automated machines, flexible circuits require additional tools to utilize the automated equipment because of their flexibility. These added tools and processes reduce the risk of errors and defects, which could lead to costly rework or even product failure.

Flexible Circuits: Design Challenges

The design of flexible circuits can also pose challenges during assembly. Flex circuits often have complex and intricate designs that require precise assembly techniques to ensure their functionality. The design must also take into account the flexibility of the circuit board, which can affect the placement of components and the routing of traces. This requires careful planning and coordination between the design and assembly teams, which requires highly skilled designers and operators.

Flexible Circuits: Material Requirements

The materials used in flexible circuit assembly also present challenges. Flexible circuits are often made using thin and delicate materials that require careful handling to avoid damage. In addition, the material must be able to handle the high temperatures needed to solder components on the circuit without any damage to the circuit itself.

In short, you need a manufacturer that understands the complex material requirements of building circuit boards.

Circuit Boards: Dependency on Experienced Talent

The final challenge of flexible circuit assembly is the need for highly trained personnel. It requires designers and operators who understand the process very well and can plan the tools accordingly, as each circuit has its own unique requirements.

Additionally, the manufacturing equipment must be regularly maintained by experts to ensure it remains in good working condition. It may need to be adjusted periodically during the assembly process.

Flexible Circuit Boards: The Bottom Line

In conclusion, the assembly of flexible circuits presents several challenges that manufacturers must overcome to ensure their reliability and functionality. These challenges include the complexity of the process, the need for specialized equipment, the design of the circuit and the materials used, and finding the right people to get the job done. However, with proper planning, training, and equipment, the best manufacturers can successfully assemble flexible circuits that meet the needs of their customers.

COVID-19 Statement and Information from Tramonto Circuits

Important information related to COVID-19 @ Tramonto Circuits

Important information related to COVID-19 @ Tramonto Circuits

Tramonto Circuits is committed to providing the same reliable service during these challenging times as we do typically and at the same time provide a safe and healthy work environment for our employees, customers, and suppliers. Our employees understand the importance of the products we provide to the current environment including those products that are used to help the medical industry in this particularly important time.

Please see the list below of actions we are taking, effective immediately to accomplish this.

No non-employees will be permitted in Tramonto Circuits facilities until further notice

All travel to customers or suppliers has been suspended

All employees are stationed at least 6 feet from each other to comply with best practice information sourced from the U.S. Center for Disease Control

A process is in place that includes frequent hand washing with antibacterial soap and hot water

Tramonto Circuits is committed to providing seamless service that feels the same as it always has with a priority on our employee’s and customer’s safety.

We appreciate your business and look forward to continued service during these unprecedented times.

![]()

![]()