What to Expect From your PCB Manufacturing Partner

When you are trusting your design to a manufacturing partner, your expectations for how you’ll be taken care of should be high. Losing time during the process means losing money on your hard-earned project and your PCB manufacturing partner needs to know that. Here are a few things to keep in mind when choosing the right partner to help you with your PCB design.

They go above and beyond

A good manufacturing partner will keep track of items with longer lead times for you to keep things organized and on schedule. A design engineer’s job is not to keep track of all those things himself or herself.

They stay on or ahead of schedule

A good PCB manufacturer should be able to identify quickly whether a design is going to have a mistake on its first round of boards. Their goal should be to help you get right through to the first round of testing sooner than later.

They deliver on time

On-time delivery seems to be a lost art these days. Tramonto Circuits makes it a priority. We understand that if we don’t deliver to our customers on time, they lose money. A 70% on-time delivery rate is roughly the industry standard. Tramonto Circuits reaches between a 98.15 – 99% on-time delivery rate year after year.

They communicate with your suppliers

You should be able to get intelligent answers from your manufacturing partner. They should be able to speak the language with your suppliers. For assembly partners, they should be able to communicate with your production people and make sure they fully understand the customer experience your product is supposed to deliver.

Learn how Tramonto Circuits has continually exceeded expectations for design engineers since 2008.

What are the Most Common Industries that Utilize Flexible Circuits?

Flexible circuits consist of thin, lightweight electrical circuits that conform to small spaces and contoured 3D shapes including cubes and cylinders. Tramonto Circuits works together with companies in a number of industries to produce high-quality, cost-effective flexible circuits and electronic components to meet their design requirements. We understand that every application is unique and not one size fits all when it comes to circuitry solutions, so we offer a diverse range of solutions for all types of industries. Here are some of the most common industries in which you will encounter flexible circuits.

Consumer Electronics

Items like paintball gun devices, invisible fence dog collars, lighted gift cards, and the fitness trackers and smartwatches you wear include flexible circuits. Tramonto Circuits supplies manufacturers of these products with smaller, lighter, easier-to-use, functional flexible circuits. Current trends tell us that consumers are looking for products that make everyday life more efficient, fun, and flexible and that is our focus when helping design engineers with consumer electronics products.

Medical Devices

The very critical nature of medical devices is not one to leave to chance. In life or death situations, accuracy, dependability, and exceptional quality matter.

Here are just a few of the areas in which Tramonto Circuits is proud to have earned a solid reputation:

- Blood analyzers (used to test COVID-19 virus and antibodies)

- Electric wheelchair safety circuits

- Diagnostic imaging for throat and esophagus

- Medical biological diagnostic equipment

- Medical perfusion machines (keeping organs at body temperature for transplants)

- BioTech Devices for educational labs and classrooms

- Field alcohol detection devices

- Specialized devices used during elective surgeries for pain management and speedier recovery

- Field drug detection devices

Our specialized flexible circuits play vital roles throughout the medical community. They also play a role in transportation, industrial applications, aerospace, and more.

Learn more about Tramonto Circuits’ many industry capabilities and contact us today for a quote.

Tramonto Circuits Achieves Near Perfect On-Time Delivery Rates and Overall Quality Ratio in 2021

Tramonto Circuits has upheld an electronics manufacturing industry reputation of providing on-time delivery to its clients and maintaining a high overall quality ratio for almost 15 years. In 2021, Tramonto Circuits achieved 98.15% on-time delivery and a 99.83% overall quality ratio.

2021 was a challenging year for all industries, especially manufacturing. Supply chain issues and long delays caused headaches all around. Tramonto Circuits was still able to maintain a very good on-time delivery rate against all odds because of its unrelenting commitment to customer service.

“I’m very proud of what we were able to achieve in 2021. The Tramonto Circuits team did an incredible job sticking to our core value, which is to help our customers every step of the way for their unique business solution needs. Our consistent communication, 24-hour quotes, and love for electronics helped us all power through an unprecedented year together,” said John Talbot, President and Owner of Tramonto Circuits.

Contact Tramonto Circuits today to ensure your next manufacturing project is completed to your complete satisfaction.

3 Things to Know About Printed Circuit Boards (PCBs)

One of Tramonto Circuits’ 3 core services is printed circuit board (PCB) design, manufacturing, and assembly. With that said, our team knows PCBs better than the back of their own hands. Here are a few basics to know about PCBs.

1. PCBs are all around us

PCBs make our lives easier by connecting the electronics of everyday life. They are found in computer motherboards and just about every piece of technology we use today such as microwaves, smoke detectors, and LED’s. From medical field solutions used by doctors to computer monitors for business and entertainment systems, Tramonto Circuits can manufacture and assemble reliable PCBs at scale with quick turnarounds and dependable on-time delivery.

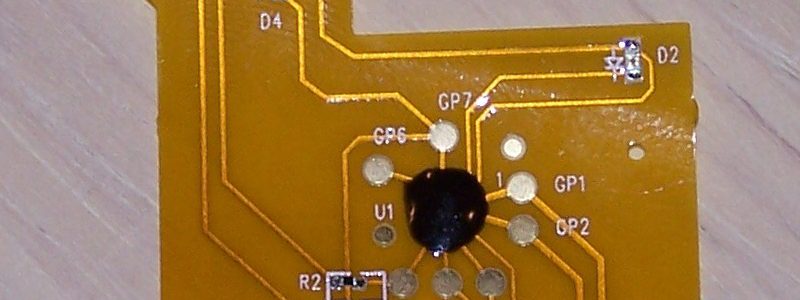

2. There are a few types of PCBs

PCBs can be either single sided circuits, double sided circuits, or multi layered circuits. These each have unique construction qualities, temperature ranges, qualification metrics and performance specifications, and design capabilities. They vary in layer count, hole size, copper thickness, and more.

3. PCBs undergo extensive testing

All of our circuit boards meet the necessary qualifications and performance specifications. Tramonto Circuits offers value-added solutions like testing to make sure you’re always satisfied with your circuit assembly results. We do functional testing of flexible circuits, flexible heaters, and PCB assemblies. We perform strain relief techniques to provide robust transition from flexible circuits to rigid stiffeners or connectors. You can be sure your circuits will meet all IPC standards with Tramonto Circuits.

Have a project? Request a quote or contact us for a free design for manufacturing analysis.

3 Things you Should Expect From your PCB Design & Assembly Partner

Finding the right design and assembly partner for your printed circuit board projects can sometimes be a game of trial and error. If you’re starting a new search for the right partner or considering switching to a more reliable company, commit to these three expectations. This will set you up with strong standards and give you clarity during your search.

1. On-time delivery

Plenty of excuses can always be provided as to why your circuit board project cannot be delivered on time. Design engineers have heard them all. At Tramonto Circuits, we have a 99.4% on-time delivery rate. So, we are telling you that you absolutely should expect your assembly partner to work to meet your timing requests.

2. Responsiveness…from a human

When you’re in a crunch to get your circuit board project completed, an auto-response isn’t going to make anything better. With Tramonto Circuits, you can expect to be able to reach a human when you need to. We’ll provide you with an update on your project so you know what to expect.

3. Fast quotes

Shopping around for a design and assembly partner isn’t like a leisurely stroll through the mall. We understand that engineers want to find the right person soon and that time is money. Tramonto Circuits quotes our customers within 24 hours. That is our promise and we’ve been sticking to it for years.

Have a project? Request a quote or contact us for a free design for manufacturing analysis.

3 Ways Your PCB Manufacturer Can Go Above and Beyond

Tramonto Circuits is known by its loyal customer base as a company that works with them to provide solutions. Many of the products supplied by our company started out with a phone call that sounded something like this: “I know this can’t be done because we’ve talked with many other suppliers, but…” They’re relieved when the answer is “I think that can be done. Tell me more about it.”

Over the last 14 years, we have worked with a lot of talented companies and engineers developing cutting edge products and pushing boundaries that spur growth. These customers deserve to know that they have a partner willing to work as hard as they do to provide consistent, reliable solutions. Here are some of the ways we go above and beyond for our customers.

1. Understand their specialty

The engineers at Tramonto Circuits come from product development backgrounds. That provides us the luxury to speak the same language as our customers and have similar industry experience. Our advantage is that we know first-hand how important on time delivery and quality circuits mean to their teams. It is the difference in getting to market before their competitors and not!

2. Diversify your offerings

It’s true we’re very good at finding solutions to challenging assemblies. However, we’re also very good at fabricating standard PCBs and flexible circuits as well. Bare PCBs from 2-20 layers and flex circuits from 1-6 layers are standard for our company. The mix of products shipped from Tramonto Circuits is about half bare circuits and half-assembled circuits. We ship ALL of our products on time so our customers never have to worry that their schedules will slip. This has proven valuable in creating happy customers since 2008.

3. Ship on time

Tramonto Circuits was founded on two principles: Ship on time and ship circuits that meet all customer requirements. We’re proud to publicly post our progress each year in these two categories. Currently, we have a 99.4% on-time delivery ratio and 99.8% overall quality ratio. These key progress indicators have improved every year that we’ve been in business. The founder chose those two principals principles because of past experiences and the company has feverishly defended them. We feel it’s an important part of why our customers stay with us long term.

Have a project? Request a quote or contact us for a free design for manufacturing analysis.

Why you Should Always do a DFM Analysis

Let’s get this out of the way – You should always perform a design for manufacturing (DFM analysis) of your products. Because Tramonto Circuits can review your circuit files free of charge, we’ll provide you a few more reasons why to get this done (as if that wasn’t enough!).

You’ll meet the IPC standards – Trust us, it is better for everyone all around to meet the necessary standards in order to avoid any headaches or safety issues. This also allows you to gain more confidence in your circuits.

You’ll achieve a higher success rate with the first design – Why have to go through multiple design rounds and spend more time if you don’t have to?

You’ll receive helpful guidance – Why go through this alone? Tramonto Circuits is here to help circuit designers along the way, with no strings attached. We mean that.

You can get your Gerber files taken care of – The team at Tramonto Circuits is happy to return these for you.

You’ll have support even after completion – The project is never complete after it hits the market. You will want someone to support you with all that comes afterward.

Ready to get started? Contact us for a free design for manufacturing (DFM) analysis.

COVID-19 Statement and Information from Tramonto Circuits

Important information related to COVID-19 @ Tramonto Circuits

Important information related to COVID-19 @ Tramonto Circuits

Tramonto Circuits is committed to providing the same reliable service during these challenging times as we do typically and at the same time provide a safe and healthy work environment for our employees, customers, and suppliers. Our employees understand the importance of the products we provide to the current environment including those products that are used to help the medical industry in this particularly important time.

Please see the list below of actions we are taking, effective immediately to accomplish this.

No non-employees will be permitted in Tramonto Circuits facilities until further notice

All travel to customers or suppliers has been suspended

All employees are stationed at least 6 feet from each other to comply with best practice information sourced from the U.S. Center for Disease Control

A process is in place that includes frequent hand washing with antibacterial soap and hot water

Tramonto Circuits is committed to providing seamless service that feels the same as it always has with a priority on our employee’s and customer’s safety.

We appreciate your business and look forward to continued service during these unprecedented times.

![]()

![]()

Tramonto Circuits Achieves 99.14% On Time Delivery in 2019

Tramonto Circuits Achieves 99.14% Overall On Time Delivery in 2019

Aggressive Key Performance Indicators Results.

ST. PAUL, Minn. (PRWEB) January 08, 2020 — Tramonto Circuits a circuit manufacturer is proud to announce that overall On Time Delivery (OTD) in 2019 increased to 99.14%. This key performance indicator confirms Tramonto Circuits’ commitment to improvement and customer requirements.

Customers Demand OTD

Motivated by a company poll that showed customer’s top two requirements for their printed circuit board suppliers were “quality” and “on time delivery” Tramonto Circuits set aggressive goals and included them as Key Performance Indicators (KPI) again for 2019. The goal set for OTD was 98% overall and the goal set for Overall Quality Ratio OQR was 99%.

2019 Results

The overall OTD improved to 99.14% and our Overall Quality Ratio in 2019 calculated by number of returned circuits vs number of circuits delivered was 99.77%! These numbers, although lofty, show the commitment the company has made to its customers. “We have improved our OTD by 0.3 points, but are nearly perfect! Achieving this kind of record despite 50% of the part numbers including assembly is unheard of in our industry,” said John Talbot President. “We have mightily surpassed our goal of 98% for 2019 and now strive to keep our OTD for 2020 over 98%. Our staff is proud of the accomplishment and look forward to more improvement in 2020.”

ABOUT Tramonto Circuits

The mission of Tramonto Circuits is “To consistently provide its customers with high quality electronic

products and services that meet or exceed their expectations.” A manufacturer of flexible and rigid printed circuits, Tramonto Circuits provides electronic circuits and assemblies to Original Equipment Manufacturers worldwide. Tramonto Circuits is based in St. Paul, Minnesota. More information is available at http://www.tramontocircuits.com.

Download in PDF form here https://www.prweb.com/pdfdownload/16816334.pdf