Should you use flexible printed circuit boards (PCBs) in your devices?

This guide explains the pros and cons of flexible circuits so you can decide if they’re suitable for your device or application.

What is a Flexible Printed Circuit Board?

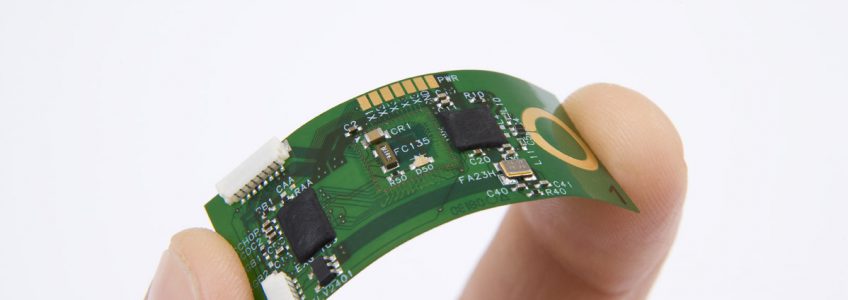

A flexible PCB is a circuit made from dielectric substrate film materials that can bend and twist without breaking. Electrical traces are etched into the surface. Once that’s complete, a protective overlay or cover coat is applied.

Flexible PCBs can be single- or double-sided and also come in multi-layered designs. Designers often combine them with rigid circuit boards to make rigid-flex circuits.

Flexible Circuit Boards: The Pros

Here are some of the positive aspects of using flexible circuit boards.

Pro: More flexible

Naturally, the critical advantage of flexible PCBs is flexibility. You can bend the circuit board to install it into a device. This allows you to build the device you want without structuring it around a rigid circuit. You can bend circuits into virtually any shape to fit any application. They can twist and bend around corners without getting caught on parts.

The entire board is flexible and stays that way for its entire useful life. The materials will not become rigid with age if designed and built correctly. The flexibility should not have any negative impact on the functionality of a device or application.

Pro: Lighter weight and takes up less space

Flexible PCBs are lighter and have slimmer profiles than traditional rigid boards. Instead of being forced to design devices and applications with extra space to fit rigid boards, you can design slimmer and more ergonomic items with flexible PCBs.

Two more pluses are that flexible PCBs help manufacturers reduce material waste and optimize their devices’ interior spaces and functionality.

Flexible PCBs do not add significant weight to devices, applications, and components. You never need to reinforce the interior of a device to support the flexible PCB. You can also meet the required weight and space limitations of items, which is particularly important for wearable technology, medical devices, and aerospace applications. Adding extra weight to these things could make them unusable or negatively impact functionality.

Pro: Replaces components and cable harnesses

When you use a flexible PCB, you do not have to add components or multiple rigid PCBs to support certain functions because they can’t get around internal components. A rigid-flex PCB can be used instead, eliminating cable harnesses. Rigid-flex PCBs are typically thinner than traditional cable harnesses, optimizing the space and weight of internal components.

ZIF connectors can be used to attach a flexible circuit board to a rigid one. ZIF connectors have a wide signal range, including low-level, high-current, and high-speed controlled impedance.

Flexible Circuit Boards: The Cons

Con: Higher cost and longer development time

Flexible and rigid-flexible PCBs cost more to build and have longer build cycles than traditional circuits. That’s partly due to the nature of the flexible materials and the relative newness of the technology. The higher costs may be prohibitive for some projects, such as when the materials and manufacturing of the device cost less than the flexible PCB. However, in the right circumstances, an extra investment in flexible PCB design and development will pay off in a big way.

Con: Size and space limitations

While flexible PCBs have slimmer profiles than traditional rigid ones, they come with size limitations. They cannot be made into very long or wide widths. Plus, flexibility in tight areas may require redesigning the components so they have lower profiles, or you may have to rework component placement to accommodate the flexible PCB. You must also be careful as the flexible PCB can be more prone to damage during handling.

Con: Increased design and stack-up complexity

As the design and stack-up of a flexible PCB increases, so does its complexity. You must follow several guidelines when using flex PCBs to prevent damage and malfunction. Some guidelines include:

- Never use plated through hole vias at bend areas

- Avoid 90-degree bends that can increase the likelihood of damage

- Conductors smaller than 10mils must be placed on the inside of the neutral bend axis and should run perpendicular to the bend

- Conductors must be staggered on multi-layered circuits.

You must also carefully consider the types of coverlays, flexible solder masks, stiffeners, and adhesives used in flex circuits. The materials differ from those used in rigid PCBs, which can increase costs and change the thickness of the board.

The Pros and Cons of Flexible Circuits: The Final Word

Flexible PCBs are becoming the go-to component for small, thin, and lightweight equipment. They allow applications to function properly while maintaining a smaller profile than equipment using larger traditional circuit boards.

Not sure if flexible circuit boards are the right solution for you? The experts at Tramonto are always available to help evaluate your application and advise on the proper circuit type for it.